Technology

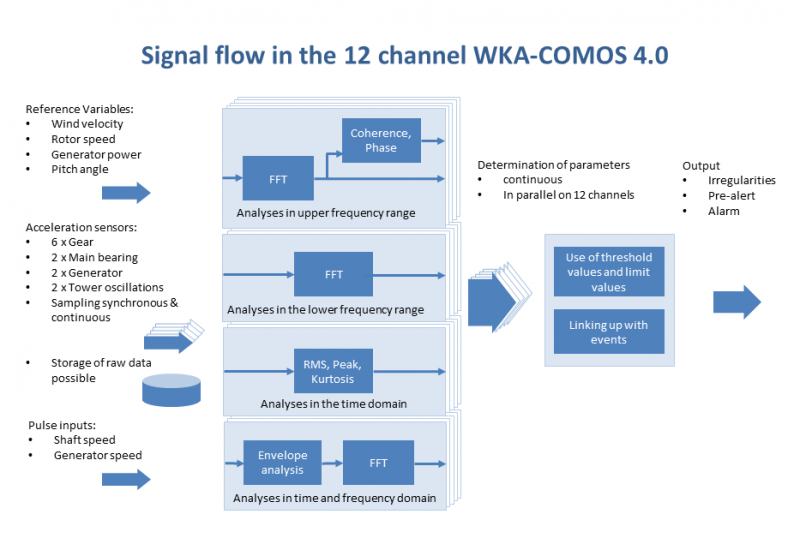

The basic principle of powerful digital signal processing for early damage detection is based on monitoring by means of time and frequency selective methods, which are combined. The basic algorithms are established in the nuclear technology for over two decades. These basic algorithms used are complemented by new task-specific analysis algorithms.

The monitoring of the time domain is designed for deterministic signal components and gives instant response to load transients. Material changes are finally recognized by a comparative analysis. This method favours the tracking of machine loads that are caused by dynamic forces, imbalances or thermal transients.

The frequency analysis, however, is designed for stochastic and deterministic signal components and also shows indirect responses to operational influences. Due to averaging procedures there is a high sensitivity to any change in the signal composition. The advantage of this method lies clearly in the evaluation of the machine condition regarding wear and retrofit measures.

Using these methods COMOS can also provide information on current issues as well as carrying out the classic functions of condition monitoring systems, such as icing or misalignment of the rotor blades.

Monitoring in the time domain:

- Peak value

- Effective value

- Crest factor

- Kurtosis

- Command variable-dependent raw data storage (wav/bin)

- Vibration velocity

Frequency domain monitoring:

Free-run spectra:

- Amplitude spectra

- Coherence spectra

- Phase spectra

- Envelope spectra

Vibration velocity spectra:

- Amplitude spectra

Frequency domain monitoring:

Rotor-synchronous spectra:

- Amplitude spectra

- Coherence spectra

- Phase spectra